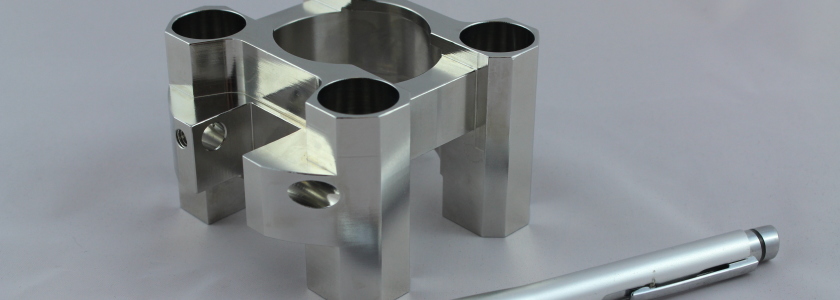

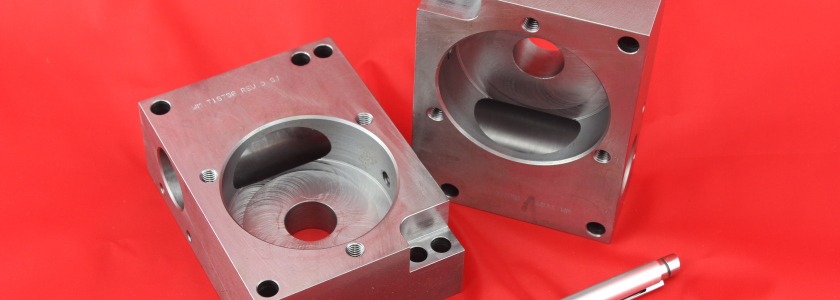

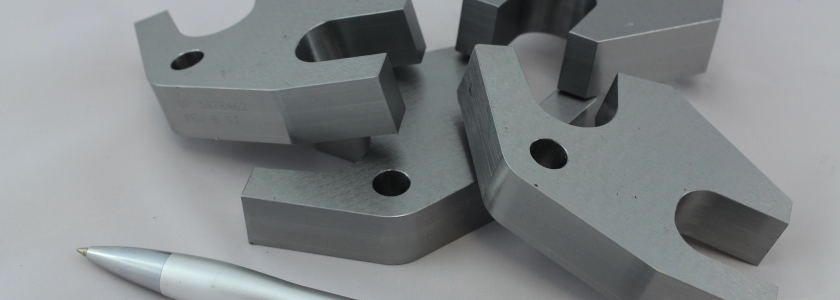

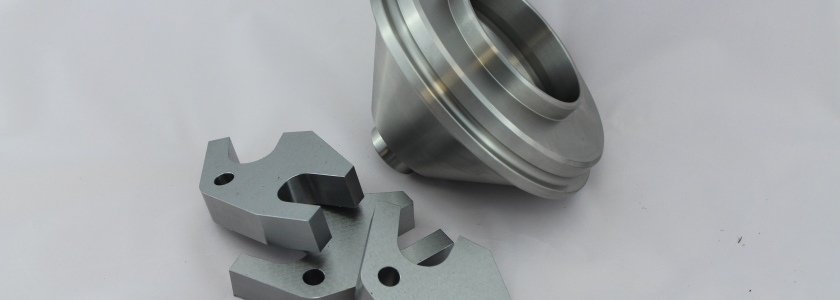

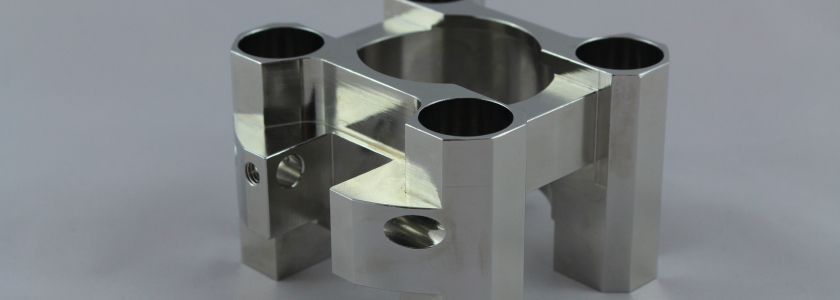

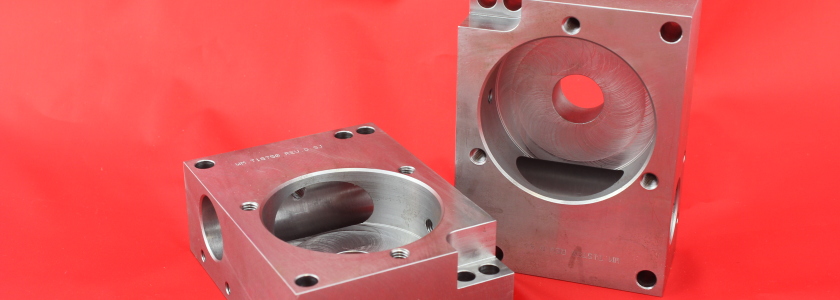

Dimensionally complicated milled parts

Although recently formed (and still constitute) a majority position in the company rotary components in recent years we have noticed a significant demand for complex milling components with higher added value. CNC milling department has therefore been greatly strengthened by several investments – especially bz 4-axes horizontal (ACE Daewoo HP500) – with indexed (1 °) fourth rotation axis and 2-pallet system for machining hydraulic blocks, gearbox housings, filter housings and similar types of products. Universal CNC milling works are permited by three classic vertical CNC centers (MX45V OKUMA, Hyundai SPT V800 and Doosan Mynx 6500 – with the table size 1400×670 mm) and most recently installed highly productive Dugard Akira RMV500APC, which is due to 2-pallet solutions deployed at larger series of pieces. Dimensionally complicated machine parts are applied by customers in typographic, but also petrochemical and electronics industries.