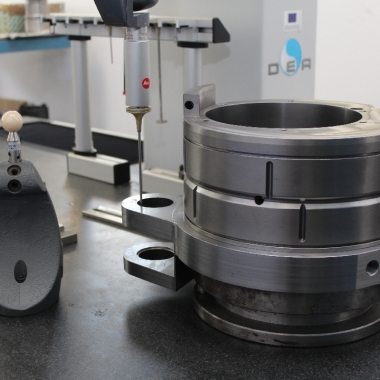

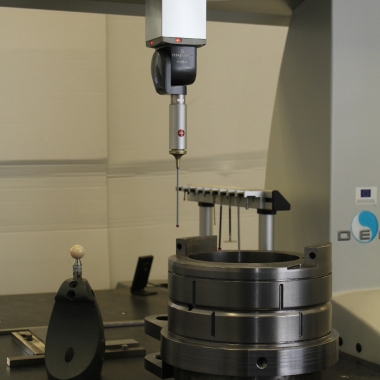

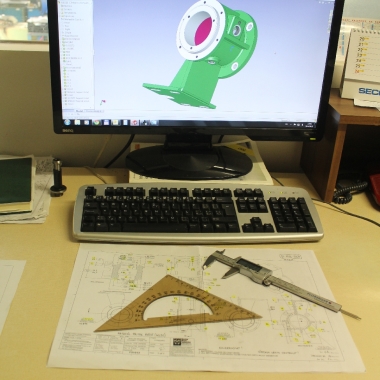

Machining

Chip removing of the material as a principal technology of the company

Machining Technology is an essential production program of the company. Continuously innovated machine park enables the company to offer the partners production of a full range of engineering components, whether these are rotary or planar parts in single and serial production. Machinew workplace space is divided into six departments:

Material division | turning | milling | grinding | drilling | Other more information