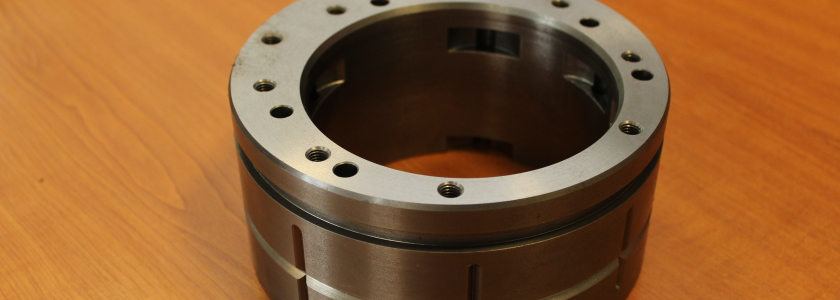

The project of the eccentric assembly of the type “roller-carrier” for offset printing

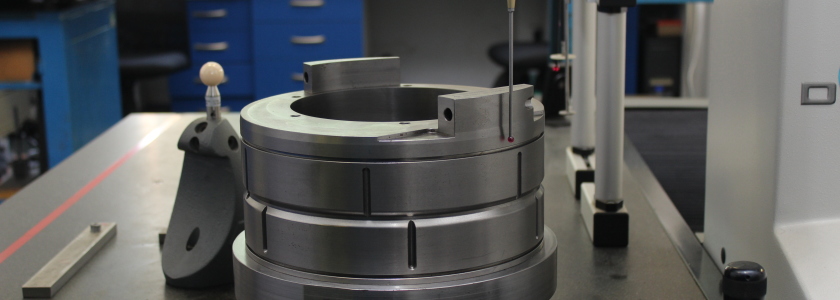

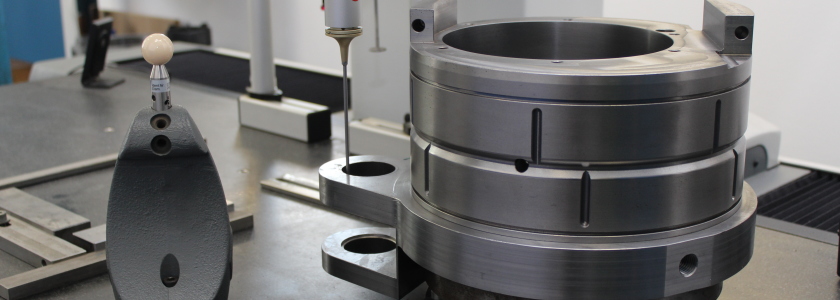

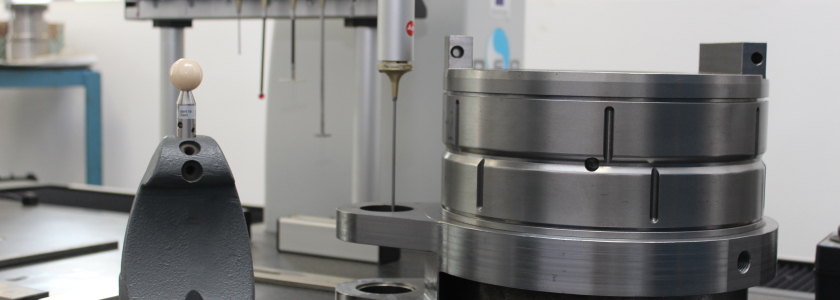

The production of these components has been implemented within the upgrade of newspaper rotary press Community from the Swedish company AB Allehanda in Örnsköldsvik in which the company SKOL Ltd. participated in the delivery of the eccentric assembly of the “cylinder clevis +” characterized also by enormous demands on dimensional accuracy (IT3 – IT4) and geometric tolerances (accuracy of eccentricity of 0.025 mm at a diameter of 200-300 mm).

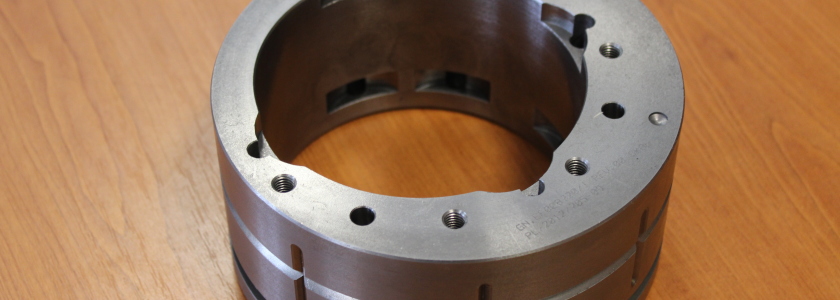

Cylinder outer diameter, d = 253.949 mm with a tolerance of 0 / -0.012 mm, an inner diameter D = 174,663 + 0 / + 0,012 mm, and the eccentricity between the averages of the critical tolerance 19 665 + 0 / + 0.025 mm, is produced from a casting of gray cast iron EN-GJL-250 and during production it is heat treated twice for removal of internal stresses. Final finishing operations are carried out in a controlled temperature range of +/- 1 ° C to avoid thermal influence outside the desired tolerance limits. Clevis outer diameter D = 276.1 mm and an inner calibric diameter D = 158.75 + 0.025 is produced from plasma quicklime burnt piece of structural steel S355J2 (former designation according to DIN 11523), which is also heat treated in the course of production. Sub-assembly cylinder + clevis prescribes the use of strength bolts 12.9 and the quality of bushings, the resulting value of precise diameters, eccentricity, the distance between the center of the cylinder and the axis of the driving hole and geometric tolerances are declared in 3D measuring lab protocol, which is attached to each supplied piece.