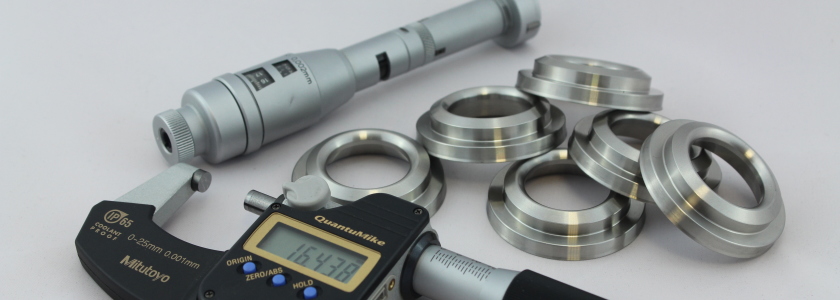

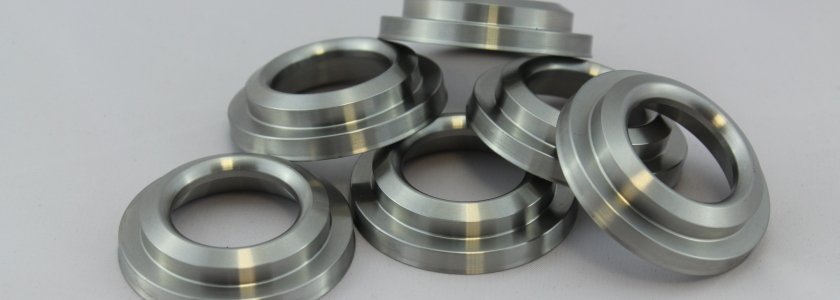

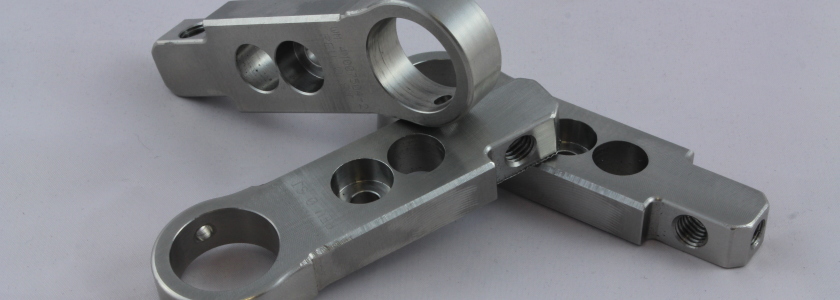

Machine components made of stainless steel, nonferrous metals and plastics

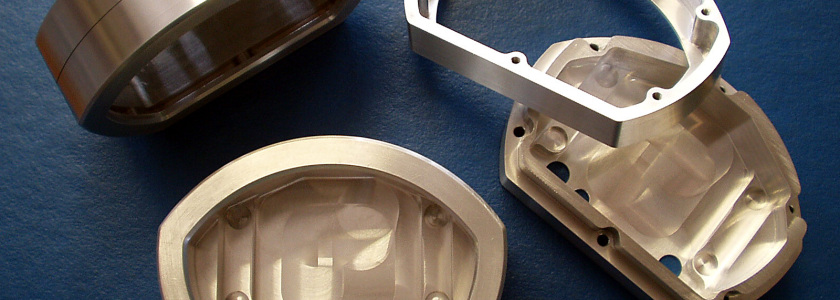

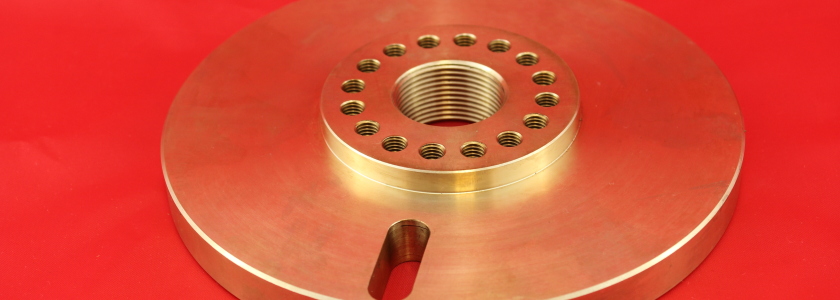

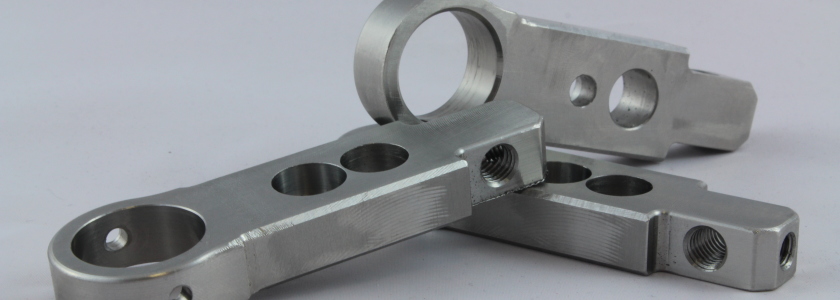

Although in the machined materials predominate steel products, approximately 20% of production is realized in stainless steel, 10-15% of the products are then manufactured from non-ferrous metals and plastics. As for stainless steel – these are especially a pressure vessel, sealing rings and other machinery components, particularly made of the following materials: steel austenitic – AISI 304 / 304L (W.Nr. 1.4301 / 1.4307, original DIN 17240/17249), AISI 303 ( W.Nr. 1.4305, DIN 17240), AISI 316L (1.4404 W.Nr., DIN 17349), AISI 316Ti (W.Nr. 1.4571, DIN 17348); martensitic – AISI 420 (W.Nr. 1.4034, DIN 17029), AISI 431 (W.Nr. 1.4057, DIN 17145); ferritic – eg. AISI 430 (W.Nr. 1.4016, DIN 17040) and austenitic-ferritic (duplex) type W.Nr. 1.4462 and W.Nr. 1.4410. Of the non-ferrous metals are used in copper alloys – brass CuZn40Pb2, CuZn39Pb3, CuZn37, or bronze – the most CuSn8, CuSn12, CuSn7ZnPb or CuAl10Ni5Fe5, but also tellurium (C14500, CuTeP) or sulfuric copper (C111 / CW114C, CuS). Aluminum alloys (EN AW 2017, EN AW 6005, EN AW 6012, EN AW 6082, EN AW 7022 and others) are mostly made of metal workpiece material. In the field of light-alloy components are an interesting project adjustable strap handles of gymnastic rings, which is an example of a simple assembly within the deliveries in terms of engineering production of non-traditional sectors of sports equipment. The principle of the report is the case with inner cone, into which is inserted a strap; loop formed around a conical insert is tightened by gravity of the sportsman (self-locking strap is secured against loosening). At the bottom of the assembly are placed balls which allow rotational movement circles. The entire assembly is made of a surface treated aluminum alloy. Plastic parts are an integral part of the production portfolio of the company – whether it’s shoes, body sensors, distance components or clues. The palette of materials used primarily includes polyamides PA6, PA66, PA66-GF30, PA6G + MoS2, polyoxymethylene POM-C, UHMW polyethylene or plastic on top mechanical properties of PEEK-type.